introduction to LED TV repair

LED TVs have gained popularity in times because of their sleek design, energy efficiency, and vibrant displays. However, like any electronic device LED TVs may encounter issues and require professional repairs. It can be quite challenging to find an affordable LED TV repair service, in Kathmandu, Nepal.

In this guide, we aim to provide you with all the information regarding LED TV repairs. We will discuss problems that often arise offer step-by-step repair instructions emphasize safety precautions when dealing with LED TVs and highlight the tools needed to execute the repairs effectively. Whether you prefer to undertake the repair yourself or locate the repair shop in Kathmandu this article of, over 3,000 words has got you covered.

Before diving into the repair process, it’s helpful to understand some of the most frequent problems that cause LED TVs to malfunction in the first place:

No Power, Not Turning On

If your LED TV will not power on at all, it likely indicates an issue with the power supply board inside the TV. Components like fuses, transformers, or power ICs may have failed. Checking voltages and continuity on the power supply with a multimeter can isolate the exact problem.

Dark, Dim, or Distorted Picture

With an LED TV, the image is produced by the LED backlights illuminating the LCD panel. So dark picture issues can mean failures with the LED strip lights or LED driver components that power them. Cables like the LVDS cable that transfers video signals can also become loose over time.

Lines on Screen

If you notice horizontal or vertical lines appear on the screen, it generally points to a defective LCD panel or T-Con board failure. Pressing gently on the edges of the LCD screen could reveal a loose cable connection as well.

Sound Problems

LED TVs utilize complex audio processing circuits, speakers, and amplifiers that can be prone to damage. Issues like no sound, low volume, or severe audio distortion require inspection of audio ICs, speakers, and related components.

Cracked LCD Panel

Cracks commonly occur from impacts or extreme pressure on the panel. Fixing a cracked LCD will require replacing the entire LCD screen assembly which can be expensive. Preventative measures include proper handling/mounting and protective bumpers.

There are other common issues like backlight bleeding, blinking power lights, wrong colors displayed, etc. But the key is properly diagnosing the root cause by methodically troubleshooting – which we’ll cover next.

Skills Needed for DIY LED TV Repair

Attempting do-it-yourself LED TV repairs requires certain skills and knowledge for safely disassembling, diagnosing, and soldering components inside modern slim LED televisions. Key skills needed include:

Electronics Repair Knowledge In-depth understanding of electronic circuits, schematics, test equipment, and troubleshooting is vital for tracing faults inside complex LED TV designs. Being comfortable reading schematics helps locate components needing replacement faster.

Soldering Skills Many LED TV repairs require desoldering surface mount ICs, ports, jacks, and other delicate components on printed circuit boards – then soldering new replacement parts. Steady hands and quality soldering gear are a must to avoid further board damage.

Attention to Safety

LED TVs have capacitors that store hazardous voltage even while unplugged. Technicians routinely get injured rushing repairs on “dead” sets before properly discharging capacitors. Safety knowledge prevents electric shocks.

For novices lacking some of these skills, hiring a professional LED TV repair company in Kathmandu is highly recommended over risking DIY repairs. But for experienced repair techs, having the proper tools and repair facility makes LED TV repairs quite straightforward.

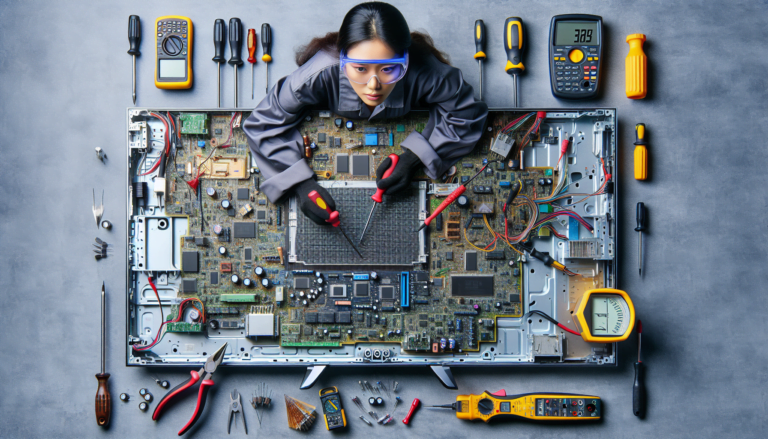

Essential LED TV Repair Tools

Equipping yourself with the right tools ensures TV troubleshooting and fix-it jobs can be performed both efficiently and safely. Here are the must-have tools we recommend for a complete DIY LED TV repair toolkit:

Multimeter – An advanced digital multimeter capable of voltage, resistance, continuity, and diode testing is arguably the most important tool for diagnosing faults before repairs can occur. They help isolate failed parts quickly.

Soldering & Desoldering Gear – A fine-tip soldering iron (ideally with variable heat), solder wire, solder wicks, flux pens, tweezers, etc allow safe removal and installation of delicate surface mount components. Quality ESD-safe desoldering stations make jobs quicker.

Precision Screwdrivers – LED TVs use very small screws to hold frames, boards and shields in place. Proper precision driver sets prevent stripping or warping delicate fasteners during disassembly. Magnetic drivers also aid repairs substantially.

Safety Equipment – At a minimum, technicians should use ESD wrist straps, latex/nitrile gloves, and insulating mats routinely. Safety goggles, face shields, aprons, and grounded heel straps also boost protection from arc flashes and electric shock during capacitor discharges.

Clean Work Surface – LED TV repair areas should be static controlled, properly lit, ventilated, and include organizational racks for parts/tools. Cluttered spaces or workshop dust invites accidental damage to delicate LCD panels or boards. Proper desks/shelving keep environments clean.

While this list covers the major tool categories, there are dozens of specialty LED TV repair tools that further aid specific jobs like pry tools, thermal cameras, board jigs, etc. But a quality multimeter and soldering station form the crux of any TV repair tech’s toolkit.

Step-by-Step LED TV Repair Process

When your LED television stops working correctly, there is a systematic process technicians follow to safely diagnose and repair the problem. The general LED TV repair procedure is:

1. Visual Inspection

Before disassembly, perform external visual checks of the LED TV set. Look for physical damage, overheating signs, bugs/pests, missing screws, wire damage, etc. Power on the TV and observe symptoms like image distortion, flashing lights, or smoke closely.

2. Discharge Capacitors Once the fault is clear, correctly discharge high-voltage capacitors inside for safety using a discharge probe and resistor. This bleeds stored electricity away safely to avoid serious electric shock.

3. Disassemble LED TV Methodically dismantle the outer shell, rear cover, metal chassis, boards, and internal framework/stands to gain access to circuits for voltage measurements and diagnostic tests next. Lay out and organize parts as they are removed.

4. Power Supply Checks

Initially focus voltage checks on the power supply board using a multimeter to probe key test points. Lack of standby or operating voltages reveals defects stopping the electrical flow, pointing to blown fuses, bad transformers, or faulty regulators potentially.

5. Mainboard Diagnostics Then shift focus to LED driver voltages, backlight power lines, and critical data/video signal paths through the T-Con, LVDS cables, and LCD panel itself. Cold solder joints on HDMI or ribbon connectors often cause signal losses.

6. Confirm Root Cause Correlate voltage drops or missing waveforms with circuit function block diagrams to isolate the damaged part(s). Confirm the diagnosis theory by testing suspected parts like ICs or armed components. Replace any severely damaged boards outright.

7. Source Replacements Order matched replacement modules, ports, and components from reputable suppliers that meet or exceed OEM specifications for performance and safety. Avoid cheap, used, or counterfeit parts prone to rapid failure after repairs.

8. Solder Replacements

Use a quality fine-tip soldering iron with flux to safely desolder and remove any faulty SMD parts, ICs, regulators, or integrated modules from the boards. Clean thoroughly and solder new replacement components into place using the steady technique to prevent lifting contact pads or damaging PCB foil traces.

9. Reassemble LED TV

Double-check all previous desolder/solder points, cable fits, component alignments, and thermal paste applications during careful reassembly. Confirm no steps were missed and no loose conductors or fragments reside on boards before rehousing in the chassis.

10. Power On Testing Following reassembly, reconnect all cables properly and power on the LED television. It should display visual content again without distortion along with proper sound. Run the TV through a full suite of tests playing varied HDR video content if issues were video or audio-related.

11. Final Validation Let the repaired LED TV run an extended burn-in test for at least 24 hours. Monitor voltages periodically to spot drops indicating flaws. If operational without faults, the repair was successful! Now wipe the TV down from fingerprints/dust before safely mounting it again protectively.

While this outlines the major phases, there can be considerable back-and-forth troubleshooting before the ultimate fix is discovered. But methodically following these LED TV repair steps in order will avoid many common pitfalls both during and after the repair which leads to success.

Common LED TV Repair Scenarios

To offer a sense of potential repair situations, here are a few of the most frequent LED TV failures with examples of fixes:

No Image Displayed

If the LED TV powers on but shows no picture, it indicates an issue with components that process the video signal rather than generate it. Troubleshooting would focus on the T-Con board, LVDS cables, and LCD panel connections searching for damage. Reseating cables or replacing a faulty T-Con board often resolves no image issues.

Dark/Distorted Image

Problems with dark, blurred, or distorted video typically start with power voltage checks. Dropout of key supply rails like 5V, 12V, or 24V to critical video components manifests as imaging problems. Cold solder joints on power regulators/filtering caps cause premature failure. Reflowing joints or replacing faulty regulators may be necessary.

Cracked LCD Panel

Serious impacts may crack the delicate LCD panel rendering the LED TV unusable. But the backlights often remain functional. Repair involves replacing the entire LCD screen assembly with a matching undamaged replacement panel. Panels with the same resolution, dimensions, and mounting holes must match to interface with the existing T-Con board.

Intermittent Sound

The sound that cuts in and out randomly points to a loose audio IC, surround sound amplifier, or speaker connectors. The problem arises from thermal expansion and board/wire movement stresses over time. Carefully inspecting solder joints and connectors for cracks and then reflowing or reinforcing resolves these common audio faults.

Blinking/Flashing Lights

LED status indicator lights that randomly flash or blink generally indicate problems sensing the correct voltage. The LED driver circuits fail to maintain a constant current to all LEDs in the string causing strobing. Replace failed LED driver ICs or individual shorted LEDs to restore normal backlight operation across the panel.

Wrong Colors Displayed

Incorrect or shifted colors shown on an LED TV mean the video signal isn’t being processed properly as it reaches the LCD matrix. Overheated transistors on the T-Con board or LVDS timing issues usually cause color problems. Cooling measures, cable replacements, or T-Con board swaps often fix color inaccuracies.

In all cases, only proper diagnostic steps narrow down the root failure among the maze of possibilities inside modern LED TV electronics. Rushing into soldering replacements without methodical troubleshooting first typically proves fruitless. Patience during repair testing pays off!

Protecting Yourself from Electric Shock

High voltage circuits capable of nasty electric shocks abound inside LED televisions – even after they are unplugged! Repair techs must follow essential safety steps before working internally:

Discharge Capacitors

Use an insulated discharge probe on wired ground straps to correctly bleed stored energy from potentially thousands of microfarad-size capacitors mounted throughout LED TV boards. This avoids accidental contact electrification.

Wear ESD Grounding

Static electricity destroys delicate TV components. Technicians must wear a form-fitting ESD grounding wrist strap with a conductive heel strap at all times when handling exposed boards or parts to channel stray static charges away safely.

Power Off AC Inlet

Ensure the main power cord is removed from the AC inlet on the rear of the LED TV to guarantee no chance of accidental re-energization during repair. Lock-out tag-out procedures are vital.

Insulate Yourself

Stand on an insulating rubber mat and avoid contact with any electrical chassis to prevent paths for current through your body. Wear rubber-soled shoes rather than leather and keep one hand in a pocket unless testing.

Use Safety Gear

Additional protection like electrical lineman gloves and insulating gloves protect hands from accidental contact with energized components. Wear safety goggles when soldering or cutting wires which may fling hot bits of debris.

Routinely Retest

Continuously verify electrical potential exists and hazard risks using a non-contact voltage tester on boards or chassis before physical contact after the unit was thought to be depleted of charges. Accidents happen when safety rules lapse.

Follow Lock-Out Procedures Before reapplying power to test repairs, carefully follow prescribed lock tag procedures at the electrical panel to avoid premature energization. Double-check check boards are properly mounted before restarting.

Staying vigilant to electrical shock dangers ensures technicians can continue helping LED TV owners for years through many repairs rather than becoming shocking statistics themselves!

Finding Reliable LED TV Repair in Kathmandu

For those lacking the technical skill, test equipment, or comfortable with safety procedures to self-repair LED TVs, utilizing a professional TV repair company in Kathmandu is the wisest choice. However, finding reliable and honest LED TV repair services poses challenges.

Get Personal Recommendations

Talk to trusted family, friends, and neighbors about their TV repair shop experience. Positive word-of-mouth praise based on real fixes carries substantial weight versus unknown paid ads or misleading prominence rankings online.

Check Repair Business Longevity

The length of years an LED TV repair shop has operated locally signifies developed competencies. Google or Facebook can indicate longevity, unlike fly-by-night operators. Dedicated storefronts also often suggest stability over transitory garage-run operations.

Inquire About Technician Training

Well-established LED TV repair companies have formally trained, experienced technicians on staff who receive ongoing education on the latest models and repair techniques as technologies rapidly advance year to year. These specialists translate to higher fixed rates.

Ask For Customer Testimonials The best indicator of service quality is positive feedback from prior customers whose similar LED TVs gained new life thanks to excellent diagnosis and troubleshooting by the repair company’s technicians and the resolve process. Client video testimonials carry substantial weight.

Compare Price Transparency Reputable TV repair shops list their service fees in advance for common repair scenarios along with reasonable diagnostic charges if issues cannot be resolved. They clarify billable expenses rather than vaguely quoting “best possible price – bring in your unit” come-ons.

Verify Satisfaction Guarantees

TV repair companies confident in their service quality offer satisfaction guarantees along with warranties on repair work ranging from 30 to 90 days from the service date. Return policies this up for any fix failures or DOA parts. Check policies before authorizing work.

Consider House Calls

LED TVs are heavy, fragile, and risky for consumers to transport between home and shop. Many premium repair firms offer pickup/drop-off service or send technicians equipped with expertise and tools directly to your home to complete repairs with minimal downtime.

Applied judiciously, these vetting criteria help locate highly qualified LED TV repair companies within the Kathmandu valley to entrust your faulty television with for diagnoses and skilled repairs. Protect your investment and avoid frustrations!

Conclusion

Rejuvenating a broken LED TV with a successful repair brings great satisfaction and avoids electronic waste. However, safely navigating high-voltage complexities requires substantial knowledge and expertise. For novices lacking specialized skills, the wise path lies in having repairs completed by a well-vetted, professional TV repair company in Kathmandu that guarantees its restoration workmanship.

We hope this definitive LED TV repair guide gave you tremendous confidence for tackling future LED television repairs yourself or selecting the perfect service shop partner to handle the job. Repairing electronics need not be a mystery with the right diagnostic mindset and passion for progressing the circular economy. Here’s to many more years of crisp images and vibrant LED displays ahead thanks to increased repairability!